3D Laser Scanner GLS-2000

Product Overview

- Speedy, precise scanning with variable range settings

- “Precise Scan Technology II” providing high quality point cloud data with reduced noise

- Full-dome scanning range

- World’s first “Direct Height Measurement”

- Easy and accurate registration methods

- Onboard software with intuitive and easy operation

-

Three models are selectable for different applications by the measuring ranges

Realizing high-speed scanning in all work steps

With the GLS-2000, true high-speed laser scanning is realized. The GLS-2000 can provide stress-free measurement throughout an entire project with increased productivity and high efficiency.

TOF measurement with improved speed

TOF measurement, with quality data with less noise, is further enhanced with ultra high-speed direct sampling technology, resulting in quick and accurate measurement.

Easy and intuitive on-board control software

With the on-board control software, the scanning can be simply started with one-touch of button. Together with color graphical display, scanning operation can be intuitively proceeded.

Dual camera

Equipped with dual camera, 170° wide angle camera (5 megapixels) and 8.9° narrow angle camera (5 megapixels) which is arranged in coaxial with the measuring axis. The wide-angle camera obtains images at high speed.

5 types of measurement mode supported

The GLS-2000 provides a wide range of measuring modes to accommodate different job site demands to achieve accurate and increased productivity regardless of site conditions.

First pulse/ last pulse selection

Depending on the location of the objects (as illustrated), a single emitted pulse from the instrument may be reflected partially by front objects (tree and net fence in the illustration) and the object in the back (house), and received by the instrument as multiple reflected beams. The GLS-2000 can recognize the “first pulse” and “last pulse” under such situation and offers first/last pulse selection to be taken as measuring result.

This technology is quite effective, especially on job sites where there are trees or fencing in front of the object to be measured.

Full-dome scanning

The instrument provides a 360° horizontal and 270° scanning measurement, capturing point clouds of objects that are difficult to measure, such as, building interiors, under bridge spans, towers, etc.

Selectable laser class (Class 3R/ Class 1)

Depending on the job site conditions, the measurement mode with different laser output power can be selected between Class 3R and Class 1 which provides eye safe measurement.

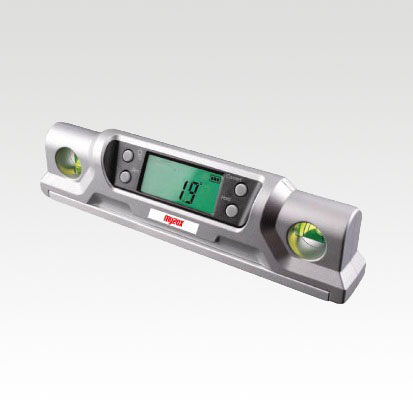

World’s First Direct Instrument Height Measurement

The GLS-2000 has an exclusive function that accurately measures the instrument height with a one-touch operation, enabling accurate point cloud measurement.

“Precise Scan Technology II” providing high quality point cloud data with reduced noise

The quality of point cloud data is further improved with the “Precise Scan Technology II” which provides much less noise and high precision and therefore clean up work of data in the post processing can be greatly reduced.

The GLS-2000 emits pulse signals three times faster than the previous model. This fast pulse signal has a clear signal wave form, and the signal timing can be detected more precisely in signal processing, which brings highly accurate measurement results.

The GLS-2000 emits pulse signals three times faster than the previous model. This fast pulse signal has a clear signal wave form, and the signal timing can be detected more precisely in signal processing, which brings highly accurate measurement results.

The GLS-2000 also employs an ultra high-speed ADC (analog-digital converter) with a newly developed direct sampling technique, that enables the extraction of a clear signal wave which is used in the measurement process.

Easy and accurate registration methods

Supporting various registration methods

The GLS-2000 can execute field work similar to that of total stations by supporting various registration methods.

- Traverse

- Tie-point

- Shape matching

ScanMaster Office software bridging scan data and CAD

ScanMaster software provides exceptional processing power to prepare 3D data for CAD applications. Featuring an array of automated functions and instrument control capability, ScanMaster dramatically increases both office and field work efficiency.